January 26, 2026

50 Views

5 min read

What’s the Future of Electric Vehicles in Trucking?

Page Contents

One missed charging window turns a profitable run into a late delivery, and that is the real tension behind electric trucks. Can an EV handle day-to-day freight work without forcing dispatch to redesign every route and buffer? The answer is increasingly yes. The outlook depends on whether charging can be planned as reliably as fueling.

How Electric Vehicles Are Transforming Trucking

Electric trucking changes the job in a very specific way: planning. A long-haul diesel route is built around fuel stops that take minutes. An EV route is built around charging windows, dwell time, and where the infrastructure exists. Diesel rigs can run 10 to 12 hours before refueling, while most electric trucks today need a two- to four-hour charge after 300 to 500 kilometers. That is why most early commercial deployments lean toward return-to-base and regional work, where a fleet controls the schedule and plugs in overnight.

The core technologies are easy to name, but they change what operators care about:

- batteries set usable capacity and range;

- electric motors deliver strong, low-speed pull;

- charging standards decide how quickly a truck returns to work.

The electric transportation industry is now building megawatt-class charging for faster turnarounds on long, busy routes. In real operations, electric and diesel trucks behave differently in ways that dispatch notices immediately:

- charging is a scheduled item, so routes are built around predictable dwell time;

- cold, heat, speed, and payload can change energy use enough that fleets keep larger buffers than they do with diesel;

- maintenance shifts from engines and aftertreatment to tires, brakes, cooling, and high-voltage inspections, with new training requirements;

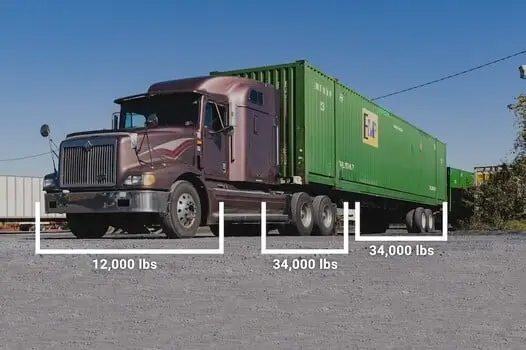

- payload can be affected by battery weight and capacity, although U.S. law allows up to a 2,000-pound weight allowance for electric (and natural gas) vehicles on the Interstate, up to 82,000 pounds gross vehicle weight.

These differences are manageable, but they demand new habits and steps and tighter adoption planning. Some manufacturers market long-range electric semi-trucks, like Tesla’s Semi, which claims up to 300 or 500 miles depending on version and fast charging that can recover a large portion of range in about 30 minutes on its system.

The limiting factor is the corridor: reliable high-power sites, grid upgrades, and charger uptime that match freight reality. Electrification is transforming trucking first, where the route is repeatable, the charging is controlled, and the numbers can be proven week after week.

Benefits of Electric Trucks

The benefits of electric transportation technologies show up first in the context of emissions rules and sustainability, operating costs, and city constraints. Here’s what changes in daily work:

- Lower local emissions and cleaner operation in dense areas, because sustainable battery-electric vehicles have no direct exhaust at the tailpipe. Even when you account for power-plant emissions, battery-electric trucks generate 60 to 75 percent less carbon dioxide over their lifetime than diesel equivalents.

- Lower routine maintenance burden, because the battery, motor, and power electronics need little regular service, there are fewer fluids, and regenerative braking can reduce brake wear.

- Quiet operation, which matters in urban delivery where noise limits can restrict early or late runs, and electric vehicles reduce that barrier.

These innovations affect route permissions, downtime planning, and how reliably a fleet keeps urban schedules without friction from neighbors, regulators, and maintenance bottlenecks.

FOR COMPREHENSIVE FLEET

MANAGEMENT SOLUTIONS

Adapting to an Electric Future

Buying an electric truck is the easy part. You’ll win or get frustrated with running this technology on time every day.

Plan the transition like an operating change. The total cost of commercial ownership goes beyond the sticker price. It includes:

- route fit and daily miles;

- electricity price structure, including demand charges;

- charger and site costs, because infrastructure can rival vehicle cost on some projects;

- maintenance and downtime expectations, because service looks different on an EV;

- incentives and resale assumptions, because they can swing payback in either direction.

Technicians need specialized training to work safely around high-voltage battery packs, inverters, and charging systems. Traditional diesel mechanics don’t learn these skills in standard programs. Courses usually cover:

- high-voltage safety and lockout procedures for technicians;

- battery and thermal system basics, so faults are recognized early;

- recovery and incident handling, including what to do after a high-voltage warning;

- driver coaching for consistent energy use, because speed, heat, and payload matter more than most teams expect.

One of the most important adoption steps here is using data to protect performance and avoid chaos. Telematics is not optional in EV operations, because the best decisions are made from real route energy data, including:

- energy per mile by route, temperature, and payload;

- state of charge at key handoff points;

- charger uptime and session outcomes;

- battery health signals.

When fleets watch these performance metrics, they can time charging, reduce missed departures, and steadily improve utilization.

The logistics companies that adapt fastest will be the ones that treat electrification as a system, including trucks, charging, training, and data. That is the most reliable way to stay competitive as EV trucking expands in the future.

Conclusion

The outlook of EV trucking technology will be decided by daily economics: route fit, charger uptime, power availability, sustainability, and predictable total cost. In the near term, electric trucks and semi-trucks keep expanding where schedules are controlled, and the fleet can charge reliably, which is why regional freight and urban delivery lead adoption. Long-haul electrification will grow as infrastructure improves and high-power sustainable charging becomes easier to build and operate. So, treat electrification as a system change in logistics and invest in training for its maintenance.

Sign up for Exclusive Trucking Tips

Test